Numerical modeling of two-phase flows in microchannels

A.A. Shebeleva1, A.V. Minakov1, D.V. Guzey1

1Siberian Federal University

Results of testing methodology for calculating two-phase flows based on the method of fluid in cells (VOF method), and procedure for CSF accounting of surface tension forces in microchannel are considered in work. Several contact angle models were considered.

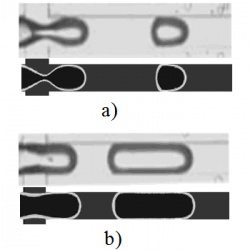

Problem is calculated using this methodology: on flow of water and oil emulsion, bubbles of nitrogen are formed in solution of glycerol flow in the gas-liquid micro channels T-type, as well as problem of simulating a water-kerosene in T-type microchannel. Comparison of numerical results with experimental data(Fig.1).

Test results show that a special role in calculation of gas-liquid flows in microchannels plays a detailing grid. This is important in field of border wall layer between bubble and solid wall.It has been found that for good simulation of gas-liquid flow in microchannels to be used over 10 calculation nodes between channel wall and gas bubble to liquid film

Problem is calculated using this methodology: on flow of water and oil emulsion, bubbles of nitrogen are formed in solution of glycerol flow in the gas-liquid micro channels T-type, as well as problem of simulating a water-kerosene in T-type microchannel. Comparison of numerical results with experimental data(Fig.1).

Test results show that a special role in calculation of gas-liquid flows in microchannels plays a detailing grid. This is important in field of border wall layer between bubble and solid wall.It has been found that for good simulation of gas-liquid flow in microchannels to be used over 10 calculation nodes between channel wall and gas bubble to liquid film

Keywords: Multiphase flows, Computational methods

Figure 1:

Results of calculation in microchannel are compared with experimental pictures:a) Qg=14 mm3/s, Ql=56 mm3/s, 25 aqueous solution of glycerin, t=5 ms;b) Qg=14 mm3/s, Ql=14 mm3/s, 25 aqueous solution of